We continue our series Bright Ideas, showcasing cutting-edge innovations from IACMI members being recognized with awards distinctions. Assessed and voted by a variety of composites industry leaders, these awards recognize groundbreaking innovations in composites and advanced materials.

Innovation: Vacuum-assisted Additive Manufacturing for Void Free Parts

Award Category: Design: Most Creative Application, 2025 CAMX ACE finalist

Company: Oak Ridge National Laboratory (ORNL) and University of Tennessee (UT)

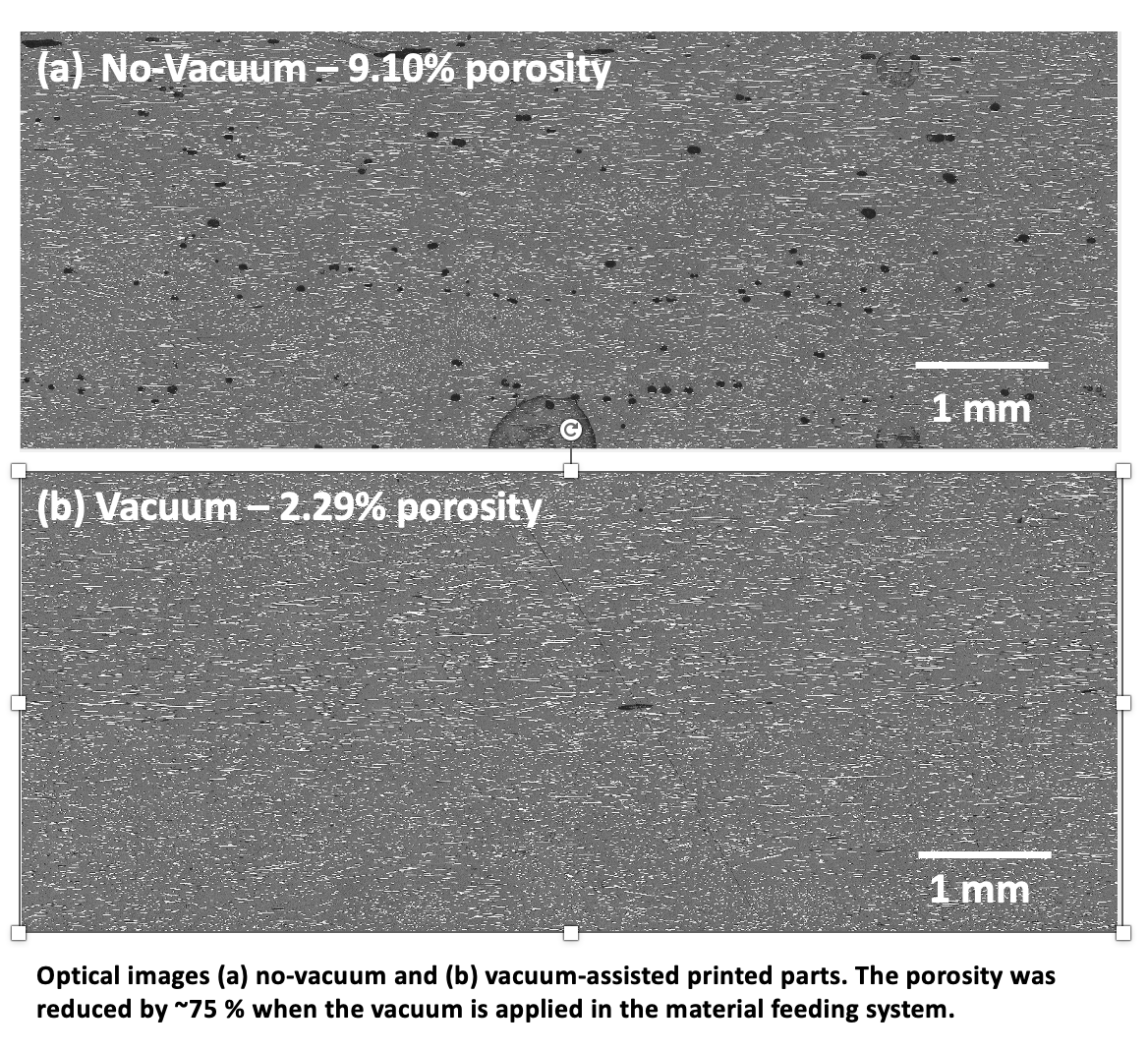

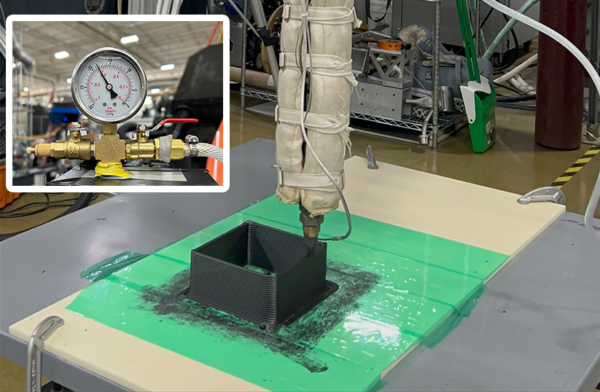

Objective: Vacuum-assisted additive manufacturing (AM) is a process that applies partial vacuum to the material feed hopper before delivering material into the extrusion barrel. This step removes entrapped air between pellets, significantly reducing internal porosity in printed parts.

Results: While large-scale 3D printing of polymer composite structures has become widespread over the past decade, most efforts to improve mechanical performance have focused on materials and print parameters to reduce inter-bead voids. However, micro-porosity within the printed beads themselves, typically 4% to 10% in fiber-reinforced materials, has been largely overlooked.

Impact: This vacuum-assisted approach lowers porosity to below 2%, enabling consistent mechanical properties and improved reliability for AM parts.

From the Experts: “We applied a partial vacuum in the hopper system, and it sucks out the air from the polymer between the pellets. When you print the part, it has almost 75% less porosity compared to a non-vacuum assisted extruded system. So, this process can really enable a void-free or less-void composites in areas where you don’t want defects in the cross section.” ~ Vipin Kumar, Senior R&D Scientist at ORNL

“While many research teams in the area of extrusion-based additive manufacturing have been focused on reducing the voids between successively deposited beads, this effort has focused on reducing the defects within a fiber reinforced polymer extrudate. If you think of printing composites as analogous to constructing a brick wall, most researchers have tried to reduce the spaces between the bricks, whereas this research was able to produce a much better brick.” ~ Chad Duty, Professor of Mechanical, Aerospace & Biomedical Engineering at UT

Learn more: https://www.ornl.gov/news/reduced-porosity-strengthens-large-scale-3d-prints and

https://doi.org/10.1016/j.addma.2024.104612